"That's How We've Always Done It" — But What If No One Remembers Why?

Generations will always move in and out of the workforce. It’s a natural cycle—but in industries like manufacturing, it can feel like watching decades of hard-earned knowledge quietly walk out the door.

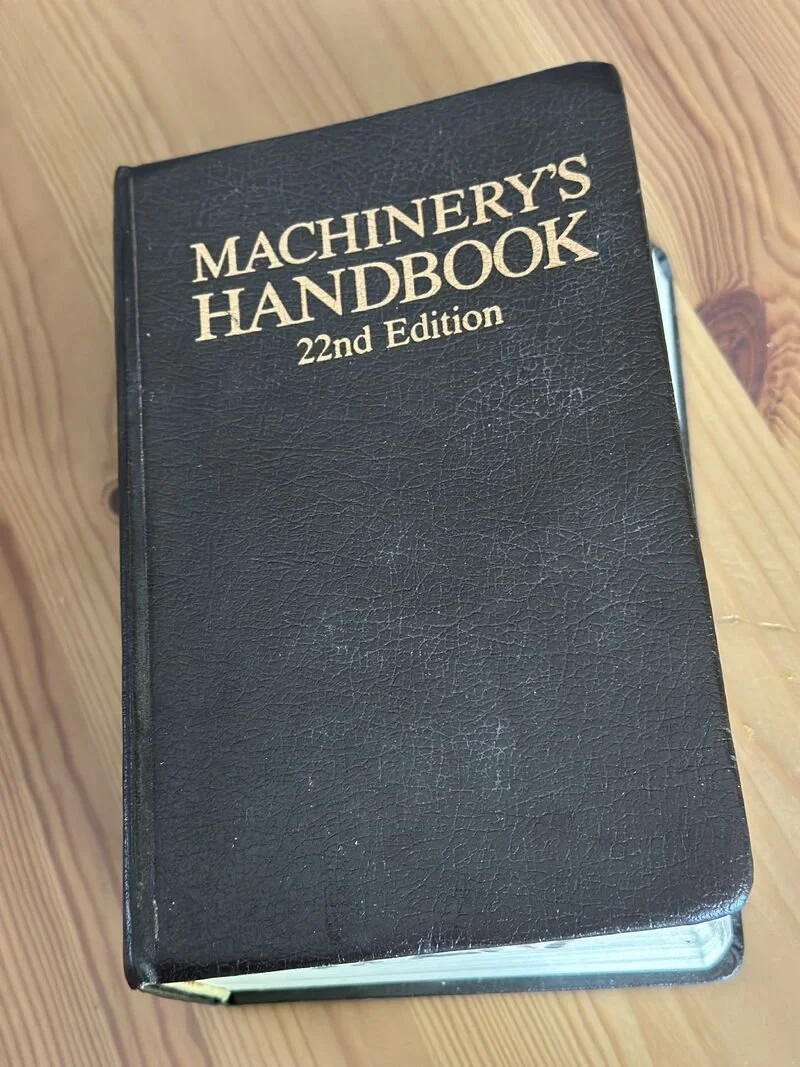

Not long ago, I met a retired plastic mounter engineer. He was once a top student, built a successful career, and even created his own “wonder book”—a personal machinery handbook full of insights gathered over decades. When he learned I work in the plastics industry, he handed it to me, hoping someone could still make use of it.

He would’ve loved to pass it on to his children—but they’ve taken different (and very successful) paths in healthcare.

So, what happens when "the one who knows" is ready to share—but "the one who needs to know" isn’t there?

At the manufacturing side I’ve worked for, we’ve seen this challenge up close. That’s why we developed a training within industry methods to support both sides of the equation—the knowledge holder and the knowledge seeker—starting from day one.

And most importantly, it allowed us to capture not just what people know—but what they can do.

Skills, not just information.

This matters not only inside the company, but across the value chain:

- Between us and our customers

- Between us and our suppliers

- Between us and our partners

Here is what organizations could do to make knowledge and skill transfer successful

✅ Standardize data capture early and often

✅ Encourage clear report writing and visual documentation

✅ Work closely with experienced team members to extract both know-how and know-why

✅ Invest early—before key skills disappear

Because “that’s how we’ve always done it” only works if someone actually remembers how—and more importantly, the why.

Let’s not lose that. Let’s preserve it—with intention and action.